One of the recommendations I made most often was to look at the opportunity of chopping more corn for silage. Even buying reasonably expensive standing corn from a neighbour will turn out to be more economical than buying in energy for the ration, or even worse, running short of feed next summer.

With the recommendation to chop more corn silage come rations that will have a higher level of corn silage as a percentage of the forages. We’ve seen a general trend towards this over the past 10 years because of the increased yield, energy density, consistency and palatability of corn silage in comparison to many other types of forage.

Cash grain prices have also made increased corn silage levels very attractive, as buying in protein supplement has remained more economical than buying energy.

The following are some things to think about whether you are currently feeding a high corn silage ration, or if your 2013 planning leads you to grow more corn silage for your dairy.

Storage

Whether using a bag, bunker, pile or upright silo, at the end of the day corn silage has to go through the same process in order to be preserved effectively. By this time of the year, pH should be below 4.0 and stable.

I always like to evaluate the feed storage on an operation before diving into the barn to evaluate the cows or ration. Simple visual evaluation can tell you a lot about the feed management on a farm.

Face management, signs of spoilage in the feed, and looking to see where any spoiled feed might be going (hopefully not into the TMR mixer) are all good indicators of the attention to detail to forage management on an operation (Figure 1).

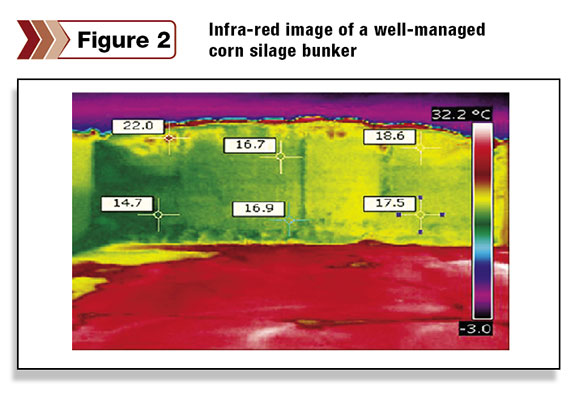

I do like to look for any signs of heating in the silage (Figure 2).

Seeing steam roll off a recently faced bunker or bag during cold weather does not necessarily indicate aerobic instability problems.

This is often just ambient harvest temperature and normal fermentation heat retained by water acting as a heat sink in the silage mass.

A better indicator of microbial-induced heating is if the silage continues to heat up after it has been removed from storage and is lying in a pile or in the feedbunk.

Evaluating harvest practices

Unfortunately at this time of year it is too late to go back and fix silage that has not been harvested as optimally as it could have been. However, this is a great time to start to ensure that the 2013 harvest gives us the best corn silage possible.

Cut length should be set at ¾-inch theoretical length of cut (17-19 mm) and all of the silage should be uniformly chopped. If you find a lot of long pieces in the bunker, it means one of three things:

1. The chopper has dull knives, which are not cutting the forage as they should.

2. The cutter bar is bent or worn, preventing the knives from making precise cuts.

3. The crop is not being fed through the machine in the proper orientation. This often happens if we have down or leaning corn at harvest.

Kernel damage is also critical to the success of high corn silage rations. The easiest way to evaluate kernel damage on farm is to use a corn silage processing monitoring cup (Figure 3).

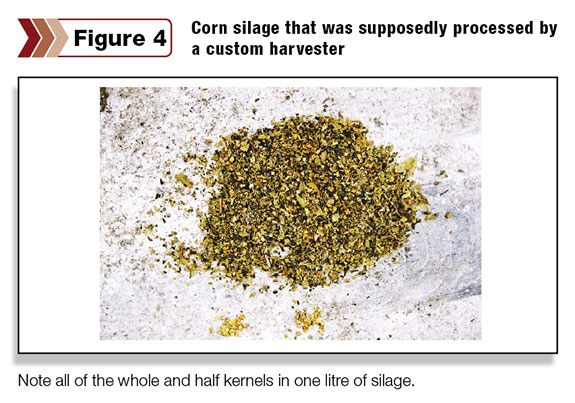

Simply scoop the cup full of corn silage, lay it out flat on the ground and remove any whole or half kernels from the mass (Figure 4).

There should be no more than four or five of these kernel pieces in the one-litre cup.

If there are, changes need to be made to the harvest process in order to optimize energy utilization for the cow.

Why would we spend the time and money to grow a great crop of corn and then not allow the cow to use it completely?

Monitoring cows

After evaluating the forages on the farm, I like to go take a look at the cows since they are the ultimate judge of how successful the feeding program is.

Monitoring cow behaviour, body condition, cud chewing, manure and the appearance of the complete TMR in the feedbunk are all important things to look for.

Sorting can be an issue in high corn silage rations as many herds have resorted to adding either straw, dry hay or both to the ration in order to help build the rumen mat and stimulate rumination.

Processing these forages to the same particle size as the corn silage and haylage in the ration will help to eliminate sorting and ensure the ration that is mixed is also the one being eaten. Ensure that there are no particles going into the ration that are wider than the muzzle of a cow if possible.

Butterfat levels are also a good indicator to monitor with high corn silage rations. Because the starch in corn silage becomes more available over time, energy levels can reach a point where we start to see some butterfat depression.

If you are feeding high-moisture corn (HMC) or cobmeal along with the corn silage, this effect is doubled because the starch in both of these crops is also becoming more digestible.

If butterfat starts to slide, discuss with your nutritionist the possibility of pulling some energy from the ration and replacing it with more forage, usually corn silage and/or haylage.

This simple adjustment should help butterfat return to the desired level and decrease ration cost due to a higher-forage ration being fed. High corn silage rations with good quality corn silage allow for very little supplemental energy to be fed.

Ration considerations

With so many different labs and ration balancing programs being used across the country, it is sometimes difficult to evaluate the rations on paper. Not all companies or nutritionists use the same values when balancing.

Not all labs report the same parameters on their reports. The following are some general guidelines I use when looking at rations. Always consult your nutritionist before making any changes.

Fibre: Nutritionists understand that they must balance the amount of nutrients and not just percentages. For corn silage, we tend to focus on NDF content (highly related to the dilution effect of starch content) and also NDF digestibility (NDFD). Nutritionists are beginning to understand that NDFD is only a guide and that even the best labs have about a two to three percentage point variation in estimates associated with these values.

This is why monitoring absolute kilograms of forage NDF intake and paying close attention to the condition of the manure is what continues to guide the ration adjustments of many field nutritionists. Nutritionists feeding high corn silage rations tend to feed slightly higher levels of NDF in the entire ration and a physically effective NDF (peNDF) level around 22 percent.

Starch: High levels of starch in corn silage have often been blamed for butterfat depression and acidosis as well as underperformance of cows being fed high corn silage diets.

As lab testing has become better and starch levels are more readily available to nutritionists, this has become a very manageable nutrient. Nutritionists now know to reduce the amount of supplemental grain being fed in a high corn silage diet to complement the high starch levels being delivered by today’s elite corn genetics.

Approximately 65 percent of the energy in corn silage comes from starch, so having a high starch level is certainly beneficial to overall ration costs.

Protein: To have success with a high corn silage ration, both protein quantity and quality need to be taken into consideration. It is important to have ample crude protein (CP) and rumen-degradable protein (RDP) in order to stimulate microbial protein synthesis.

This will help to ensure efficient use of the forages in the ration. Overfeeding protein, however, becomes very expensive, especially as the price of soybean meal has risen with the price of soybeans particularly over the past year.

Conclusions

Whether you are feeding a high corn silage ration today, or are considering it in the future, there are many things to watch out for to ensure success. Many herds in Canada are feeding high corn silage rations very successfully and when you look at the economics, it makes a lot of sense in today’s market.

We will continue to see the shift towards more corn silage in our dairy rations as long as dairy producers continue to consider both animal performance and efficiency per acre as key metrics when looking at the success of their overall operation. PD

References omitted due to space but are available upon request. Click here to email an editor.

- Robert Larmer

- Consultant

- DuPont Pioneer